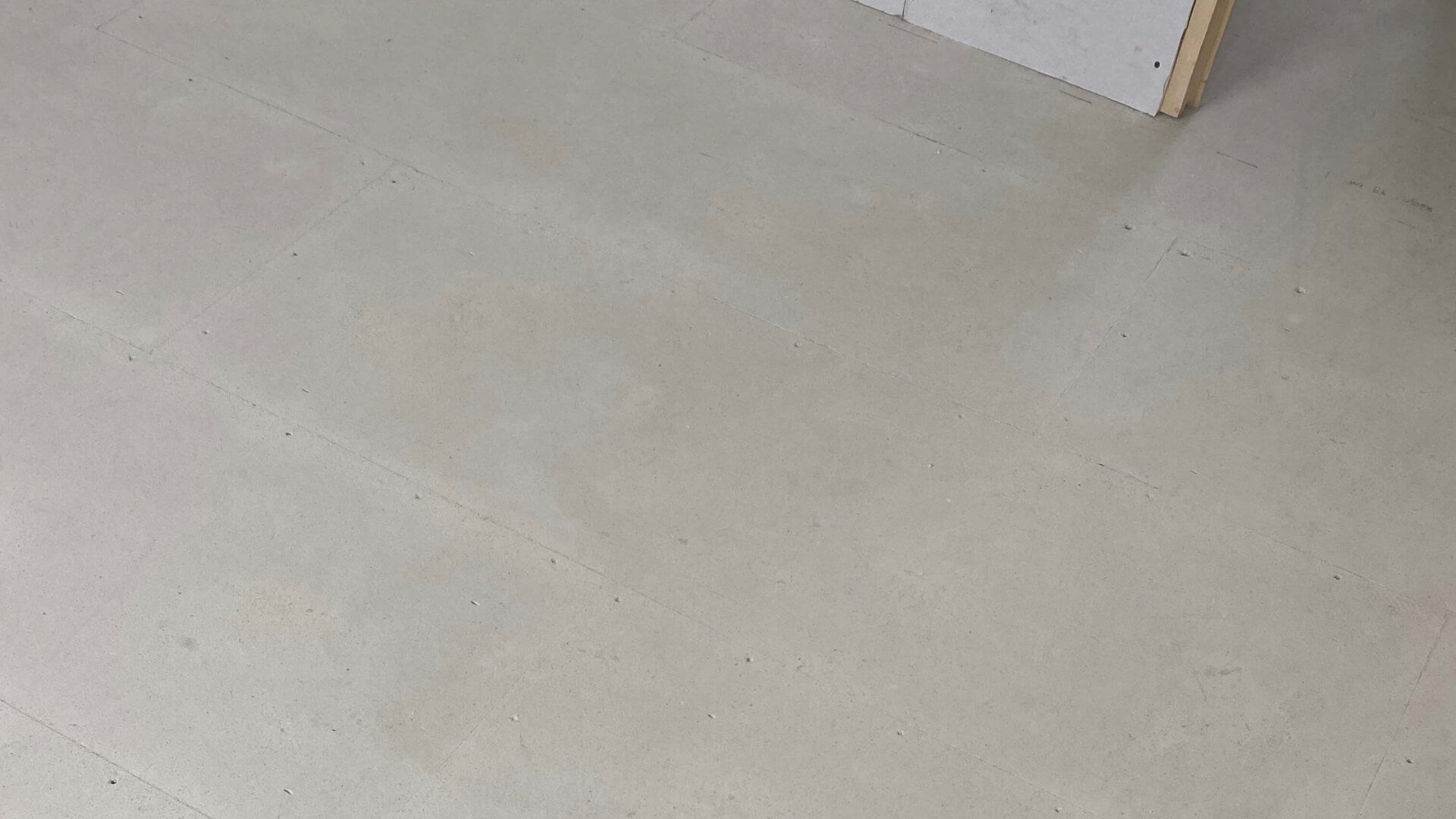

ESTRICHVLOER/ GIPSVEZELPLATEN

Bezoek de showroom

The Estrich floor on gypsum fiber boards consists of, among other things, a mixture of paper fibers and gypsum, which are compressed under high pressure.

The Estrich floors offer a major advantage over wet construction floors, because they do not need to be poured. This means they do not have a long drying time. The purpose of these floors is to level the subfloor and make it suitable for finishing with floor coverings (wood, etc.).

Through a mutual connection through lip welding, the floor becomes stable and a whole.

The floors are impact-resistant and extremely durable. In addition, the floors meet the highest requirements of the building code. The floors have thermal insulating, sound insulating and fire retardant properties.

The three best-known brands in gypsum fiber boards are: Knauf Brio, Fermacell and Redupanel. The floors can be combined with almost all finished floors, including a wooden floor.

Some of the benefits of flooring outlined:

- Quick to use, no long drying time

- Low installation height, starting from 20 mm

- Have good sound insulation

- Relatively low in weight

- Can be combined well with underfloor heating

CAN A WOODEN FLOOR ON A KNAUF BRIO FLOOR?

Knauf Brio floors are drywall panels consisting of gypsum and cellulose fibers.

During the production process, the fibers are arranged and placed in the same direction. This gives the board greater strength than other gypsum fiber boards.

The Knauf Brio floors consist of a floor plate, often combined with an insulating layer on the underside. All Knauf Brio floors have fire-retardant properties.

WHAT TYPES OF KNAUF BRIO PLATES ARE THERE?

Floor elements

Knauf brio 18

18 mm thick floor element, fitted with a milled connecting lip all around

Knauf brio 23

23 mm thick floor element, with milled connecting lip. Due to the extra thickness, this floor is intended for a higher load capacity. In addition, underfloor heating pipes can be milled into this floor element. The maximum milling depth is 15 mm.

Floor elements with noise-reducing properties

Knauf brio 18 MW

18 mm thick floor element, with 10 mm rock wool on the underside. The total thickness is 28 mm. This floor element has noise-reducing properties.

Knauf brio 18 WF

18 mm thick floor element, with 10 mm wood fiber material at the bottom. The total thickness is 28 mm. This floor element has noise-reducing properties.

Knauf brio 23 WF

23 mm thick floor element, with 10 mm wood fiber material on the underside. The total floor thickness is 33 mm. Due to the extra thickness, this floor is intended for a higher load capacity. In addition, underfloor heating pipes can be milled into this floor element. The maximum milling depth is 15 mm. Due to the wood fiber material, this floor element has noise-reducing properties.

Floor elements for the ground floor, with thermal insulation

Knauf brio 18 EPS

18 mm thick floor element, with 10 mm expanded polystyrene (EPS) on the underside. The total thickness is 28 mm. This floor element has thermal insulating properties.

CAN A WOODEN FLOOR ON A FERMACELL FLOOR?

A Fermacell floor is a very suitable subfloor for a oak floor.

The Fermacell subfloor is an Estrich floor which is available in various thicknesses and suitable for many rooms and applications. The Fermacell floor consists of 2 plates, sometimes in combination with another material at the bottom. The plates are connected to each other by the lip weld, which is glued. During installation, these plates are fixed, creating a flat floor when installed properly.

The panels can even be used when high fire safety standards apply.

Bezoek de showroom

WHAT TYPES OF FERMACELL SHEETS ARE THERE?

Floor elements for underfloor heating

Fermacell 2E11, 2 floor elements of 10 mm thick, a total of 20 mm thick.

Fermacell 2E22 2 floor elements of 12.5 mm thick, a total of 25 mm thick.

Floor elements for the ground floor with thermal properties

Fermacell 2E13, 2 floor elements of 10 mm thick, combined with 20 mm EPS, a total of 40 mm thick .

Fermacell 2E14, 2 floor elements of 12.5 mm thick, combined with 30 mm EPS, a total of 50 mm thick.

Floor elements with noise-reducing properties

Suitable on a wooden subfloor

Fermacell 2E32, 2 floor elements of 10 mm thick, combined with 10 mm mineral wool, a total of 30 mm thick.

Fermacell 2E35, 2 floor elements of 12.5 mm thick, combined with 10 mm mineral wool, a total of 45 mm thick.

Suitable on a concrete subfloor

Fermacell 2E31, 2 floor elements of 10 mm thick, combined with 10 mm wood fibre, a total of 30 mm thick.

Fermacell 2E33, 2 floor elements of 12.5 mm thick, combined with 10 mm of wood fibre, a total of 35 mm thick.

Fermacell 2E34, 2 floor elements of 12.5 mm thick, combined with 20 mm wood fiber, a total of 45 mm thick.

Suitable on wooden and concrete subfloor

Fermacell 2E16, 2 floor elements of 10 mm thick, combined with 9 mm felt, a total of 29 mm thick.

Fermacell 2E26, 2 floor elements of 12.5 mm thick, combined with 9 mm felt, a total of 34 mm thick.

Floor elements suitable for wet and humid areas

Fermacell Powerpanel, 2 floor elements consisting of cement-bound material of 12 mm thick, a total of 25 mm thick. Suitable for milling underfloor heating or laying over underfloor heating.

IS A REDU PANEL FLOOR SUITABLE FOR A WOODEN FLOOR?

Redu panel floors have a leveling ability. As a result, they are often used on wooden construction floors. Due to their thickness of 25 mm, they have a low installation height. In addition, they have a great noise-reducing capacity.

Due to the tongue and groove connection, they are connected to each other with glue. After installation, the floor can be walked on immediately.

Humidity

The humidity in the room should not exceed 70% when installing the Estrich floors. The building must be wind and watertight. When the floors are applied to concrete floors that contain residual moisture, a special foil must be used. For concrete floors with rising damp, first apply a seal to the floor, such as a moisture barrier.

The floors are a dry construction system, the floor can be used 24 hours after gluing.

HOW FLAT SHOULD A STRICT FLOOR / PLASTER FIBER BOARD BE?

The Estrich floors are glued together and are usually “loose” from the subfloor. It is important that the subfloor is flat. The plates follow any differences in the subfloor. Is the subfloor not completely flat?

In combination with leveling agents, a flat work floor can be created that is very suitable for Estrich floors and a wooden floor. The Redu Panel can often be used without leveling agents.

Magazine vol inspiratie

WOODEN FLOOR GLUED OR FLOATING?

A gypsum fiber subfloor is a stable base for gluing a wooden floor or floating in places. A wooden herringbone floor or chevron wooden floor are always fully glued. This can be done directly on the Estrich floor, without using an additional subfloor.

The floors do not need to be pre-sanded, provided the floor is free of plaster or paint residue. These ensure poor adhesion between the adhesive and the floor elements.

If you choose floor heating it is advisable to glue the wooden floor to the subfloor. This is due to less heat resistance.

With a floating installation, the wooden floor is placed on a folie posted. If the subfloor has a sound-insulating layer, we do not recommend installing the floor as a floating layer.

Laying an Estrich floor

In addition to laying the wooden floor we can provide the different Estrich floors for you. Uipkes can take care of both delivery and installation, as well as any leveling of the subfloor. In addition, we can also provide underfloor heating for you.

PLASTER FIBER BOARDS - UNDERFLOOR HEATING COMBINATION

The gypsum fiber board floor is usually used with a milled underfloor heating system. The pipes are milled into the gypsum fiber board floor. Further explanation of the milled underfloor heating system can be found here.

POINTS TO CONSIDER FOR PLASTER FIBER FLOORS

- When using milled underfloor heating , ensure that the screws are removed. To avoid this, you can opt for a spreading staple.

- Screw down loose and creaking planks on a wooden construction floor before installing the Fermacell panels.

- Place wall strips along the edges to reduce contact noise

- Remove adhesive 24 hours after installation of the floor.

- The Estrich floors cannot be applied directly to the wooden beams. First attach a sufficiently load-bearing subfloor here.

VISIT SHOWROOM

-

Alphen a/d Rijn

Euromarkt 113

-

Amsterdam

Roelof Hartstraat 4

Frequently Asked Questions

What are gypsum fiber boards?

Gypsum fiber boards, also known as gypsum fiber boards or gypsum fiber boards, are board materials that consist of a gypsum core and are reinforced with fibers, such as cellulose or glass fibers. They are widely used in construction as a finishing material for walls and ceilings.

What are the advantages of gypsum fiber boards?

Gypsum fiber boards offer several benefits, including:

- Strength and durability: The reinforced fibers provide extra strength and stability, making the plates resistant to impact and deformation.

- Fire resistance: Gypsum fiber boards have good fire-resistant properties, which means they can slow the spread of fire.

- Sound insulation: The gypsum core naturally has good sound-insulating properties, which means that gypsum fiber boards can dampen sound.

- Easy installation: They are relatively lightweight and easy to cut, which simplifies installation

Where are gypsum fiber boards used?

Gypsum fiber boards are widely used in the construction sector for various applications, such as:

- Walls: They are used as a finishing material for interior walls, both in residential and commercial buildings.

- Ceilings: Plaster fiber boards are also used as a ceiling finish.

- Fire-resistant constructions: Due to their good fire-resistant properties, gypsum fiber boards are often used in fire-resistant constructions, such as fire walls and fire-resistant ceilings.

Can I use underfloor heating in gypsum fiber boards?

Yes, underfloor heating can be milled into gypsum fiber boards. Make sure that the plates are of sufficient thickness to make the slots. It is advisable to insulate the plates from below, or to use plates that already have insulation material.

Are gypsum fiber boards water resistant?

Standard gypsum fiber boards are not water resistant. They can be damaged by prolonged exposure to water or moisture. However, there are water-resistant variants of gypsum fiber boards available, which have been treated with a water-repellent agent or have a water-resistant coating. These special plates are recommended for use in damp areas, such as bathrooms and kitchens.

Can I install gypsum fiber boards myself?

Yes, it is possible to install gypsum fiber boards yourself if you are handy and have experience with DIY projects. Make sure you have the right tools and equipment, such as a saw, screws and a screwdriver. It is also important to follow the manufacturer's installation instructions and take proper safety precautions. If you are in doubt, it is best to consult a professional.

- Choosing a selection results in a full page refresh.

- Opens in a new window.